Returns can be a profit-killer for any custom printing business, especially when they involve personalized or branded products that are harder to resell. From unclear sizing to misaligned graphics, the reasons behind returns are often preventable with the right strategies and tools. Below, we’ll explore the common pain points driving customer dissatisfaction, and how to tackle them with accurate previews, and quality control measures.

How to Reduce Returns for Custom Printed Merchandise: Addressing Common Causes

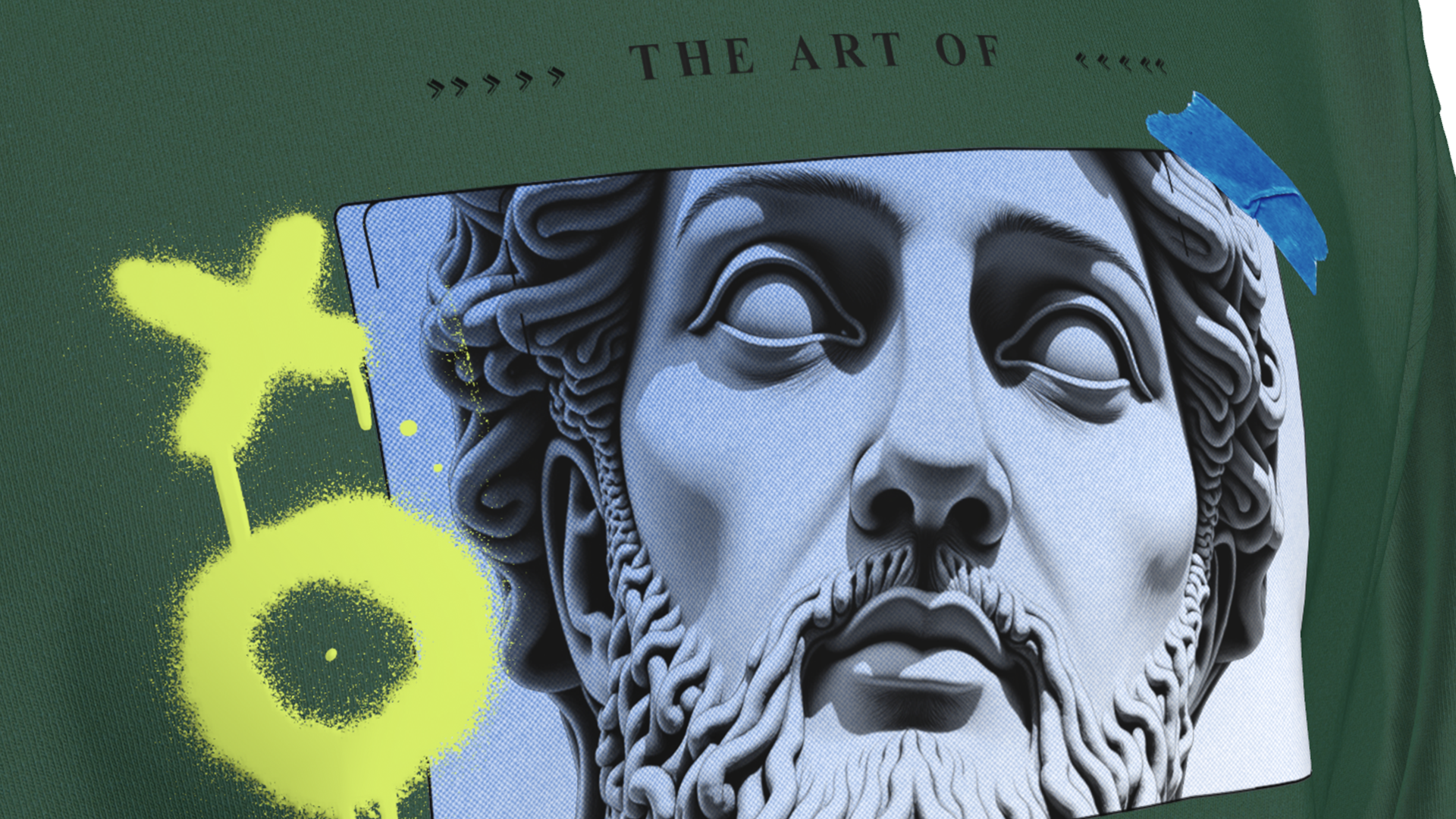

The top reasons usually revolve around incorrect sizing, poor design placement, or mismatched colors. Customers might also complain about the final product feeling different than expected—like a T-shirt that’s thinner than the images implied, or a print that’s not as vibrant as advertised. Addressing these issues means giving buyers realistic expectations and ensuring your returns process and production processes are tight. For instance, providing detailed product descriptions that highlight material weight or texture helps set the stage. Additionally, high-quality digital mockups can show fabric details, folds, shine, or other nuances of the material, letting customers see a near-physical preview before approval or checkout.

When setting up an online store or working with a customer order, consider offering helpful resources—like an FAQ explaining how your printing process works, or guidelines on how certain materials may affect color saturation. All of these efforts collectively reduce the mismatch between what the customer expects and what actually arrives.

Understanding Customer Dissatisfaction

Customer dissatisfaction is a critical issue that can significantly impact a business’s reputation and bottom line. When customers’ expectations are not met, it leads to negative experiences that can tarnish your brand reputation and drive customers away. Common causes of customer dissatisfaction include poor customer service, product quality issues, and a mismatch between customer expectations and the actual experience. For instance, if a customer receives a product that looks different from the online preview or feels of lower quality than anticipated, dissatisfaction is almost inevitable. A dedicated support team can help address these issues promptly, ensuring that customer concerns are resolved efficiently.

Identifying Root Causes of Returns

Understanding why customers return products is crucial for reducing return rates and boosting customer satisfaction. By diving into returns data, businesses can uncover patterns and trends that reveal the underlying causes of returns. Common issues include poor product quality, inaccurate descriptions or images, insufficient information. Additionally, poor customer service can exacerbate these problems, leading to higher return rates.

For instance, if a significant number of returns are due to product defects, it signals a need for improved quality control. If customers frequently cite misleading product images, it’s time to update your visuals to better reflect the actual product. By identifying these root causes, businesses can take targeted actions to address them, such as enhancing product quality, providing more detailed descriptions, and improving customer support. This proactive approach not only reduces returns but also enhances overall customer satisfaction.

Which Quality Control Measures Can Reduce Errors or Misprints Before Products Ship to Improve Customer Satisfaction?

Quality control starts well before you print the first run. It includes verifying artwork resolution, checking color profiles, and making sure each design lines up correctly on the chosen garment or product. One effective method is using a digital proofing system where every design goes through an approval round—either internally or with the client—before it hits the press. This extra step flags potential misalignment or font issues that might slip through in a high-volume scenario.

Investing in calibrated printers, regular maintenance, and accurate color matching software also pays dividends, especially if your inventory spans different materials or inks. By standardizing everything from design files to final inspection points, you create a repeatable, reliable workflow that leaves less room for human error and helps manage logistics costs effectively. Even small touches—like final visual checks against a master sample—can go a long way toward curbing unnecessary reprints and refunds.

Ensuring the quality of print materials is crucial for effective marketing strategies. This includes finishing processes, quality control, and efficient delivery systems to ensure that print materials reach consumers effectively, contributing to overall branding and customer satisfaction.

How Can Accurate Online 3D Previews Help Mitigate Returns?

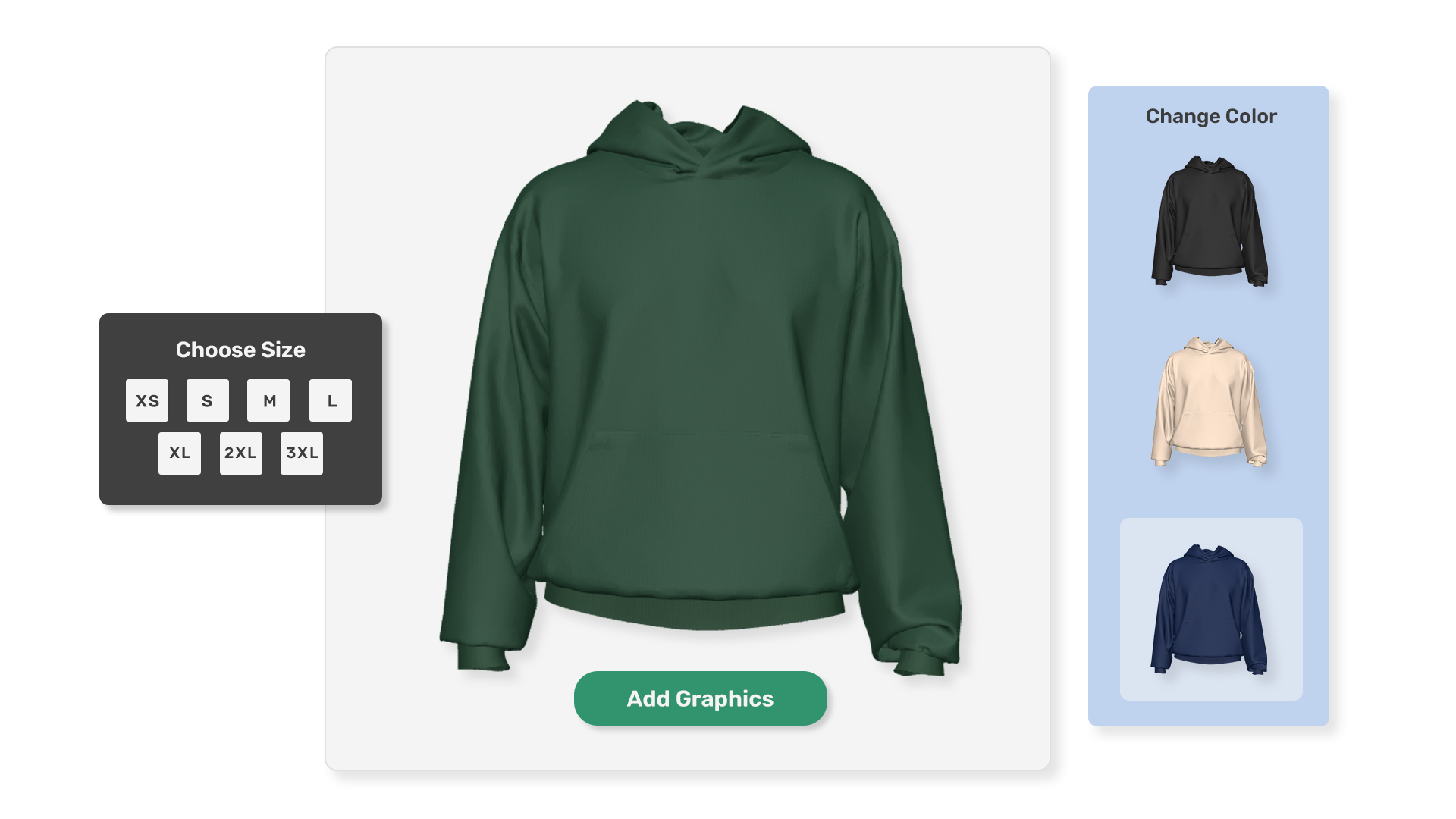

One of the best ways to reduce returns is by showing customers exactly what they’re getting before they approve an order or check out. Effective sales and marketing materials like mockups, proofs, and e-commerce images play a crucial role in communicating expectations and professionalism, especially during peak e-commerce sales periods. If your digital mockup only shows a flat, low-res image of a design, there’s a big leap between that preview and reality. In contrast, detailed 3D mockups illustrate precise design placement, proportions, and color schemes on the product itself. Buyers see how a hoodie’s pocket or a T-shirt’s seam might interact with the printed design, drastically cutting down the “I didn’t know it would look like that” factor.

Further, 3D mockups make it easier to depict how different sizes will appear on a model or mannequin, a game-changer for fit related concerns. When combined with robust size charts, this approach reassures customers that the final print will fit and look consistent with the preview, reducing guesswork and the subsequent risk of returns due to sizing errors.

What Role Do Professional-Grade Product Configurators Play in Lowering Return Rates?

Clear, accessible information isn’t just about size charts or design proofs—it’s also about using the right technology to ensure that every aspect of production meets customer expectations. Professional-grade product configurators, such as SEDDI Decorator, go beyond static visuals to create accurate, high-quality mockups in record time. The cloud-based platform allows you to preview graphic designs on 3D apparel that has been created from the garments’ real patterns, and real physical attributes, ensuring that logos, graphics, and text appear exactly where and how they should. By ensuring accurate design placement and highly detailed 3D decoration previews, errors are reduced and customer expectations are met.

Because SEDDI Decorator facilitates commenting and sharing, both you and your clients can collaborate on a single, interactive platform. Questions about placement, color, or sizing can be resolved faster, dramatically reducing the back-and-forth that typically leads to misunderstandings or errors. Once the design is approved, the software automatically generates a tech pack tailored to the product’s actual patterns, enabling production teams to follow specifications with pinpoint accuracy. This translates to fewer misprints and returns—and a smoother path to customer satisfaction.

Leveraging Returns Data

Returns data is a goldmine of insights that can help businesses refine their operations and improve customer satisfaction. By analyzing this data, companies can gain a deeper understanding of customer behavior and preferences, identify trends, and make informed decisions to enhance their products and services.

For example, analyzing returns by product category can highlight specific areas needing improvement. Examining returns by customer segment can reveal demographic trends, helping tailor marketing strategies more effectively. Returns data can also inform product development, ensuring new designs meet customer expectations. Sharing this data with suppliers can lead to better product quality, reducing defects and returns.

Building a Return-Proof Workflow for Custom Printed Merchandise with Efficient Reverse Logistics

Reducing returns for custom printed merchandise isn’t about one single tactic; it’s a holistic approach that covers quality control, accurate previews, and transparent communication every step of the way. Your goal is to match customer expectations with a product that meets (or exceeds) the visual they saw. Eliminating confusion and nurturing trust leads to fewer refunds, lower overhead, and ultimately happier, more loyal customers. By fine-tuning each stage—design, proofing, production, and shipping—and bringing on a power tool like SEDDI Decorator—you can create a seamless experience that keeps both sales and satisfaction levels high. Managing e commerce returns effectively is crucial for maintaining customer satisfaction and reducing costs.

A return-proof workflow is not just about minimizing returns but also about leveraging the data from returns to improve future sales. By analyzing return patterns and customer feedback, you can identify areas for improvement in your product offerings and customer service. By leveraging returns data, businesses can optimize their commerce sales strategies and improve overall profitability.

The Path to Fewer Returns and Happier Customers

Reducing returns for custom printed merchandise isn’t just about cutting costs—it’s about building trust, streamlining operations, and ensuring customers get exactly what they expect. From improving quality control measures to leveraging high-fidelity 3D previews, every step in your process can make a difference.

By integrating accurate product descriptions, realistic mockups, and professional-grade design tools, you minimize errors before they happen. Technologies like SEDDI Decorator help eliminate guesswork, ensuring that graphics, colors, and placements are spot-on before production even begins. Pairing these strategies with data-driven insights from returns allows you to refine your offerings, reduce dissatisfaction, and create a seamless buying experience.

Ultimately, the key to minimizing returns is alignment—between what customers see, what they expect, and what arrives at their door. The more transparent and precise your workflow, the more you boost customer confidence, protect your bottom line, and establish your business as a trusted name in custom printing.