In custom apparel, speed, accuracy, and scalability are everything. Clients want creative control, sales teams need rapid approvals, and production teams depend on precision. The difference between winning the job and losing it often comes down to workflow. That’s why building a streamlined, end-to-end process, from the first design click to final production, is no longer a nice-to-have, it’s a competitive necessity.

Step 1: Design and Visualization in a Custom Apparel Workflow

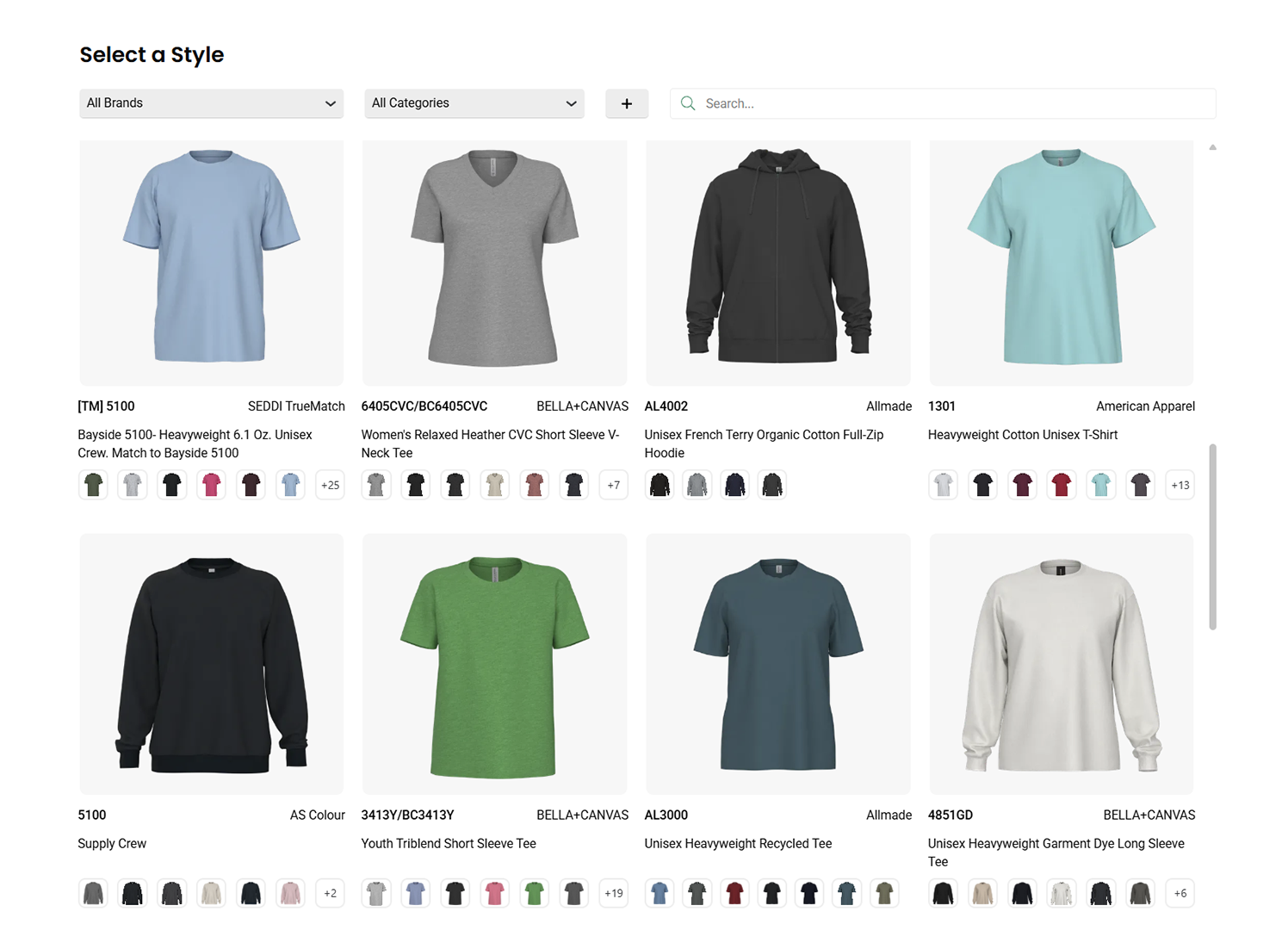

At the front end of the process is design. SEDDI Decorator sets the standard here. Rather than relying on static 2D previews or generic templates, sales teams and clients can create interactive, photorealistic 3D mockups using real brand-name blank apparel. The Decorator platform includes:

- A library of real apparel styles rendered in accurate 3D based on actual garment construction, bill of materials, and colorways

- The ability to place artwork in standard print regions across entire size ranges of styles

- High-fidelity texture and color rendering—including fabric drape, stitch-level detail, and decoration technique visualization such as puff or plastisol

- Real-time collaboration, sharing, and commenting with teammates and customers in an interactive, 3D environment, to ensure high-quality visual representations throughout the process

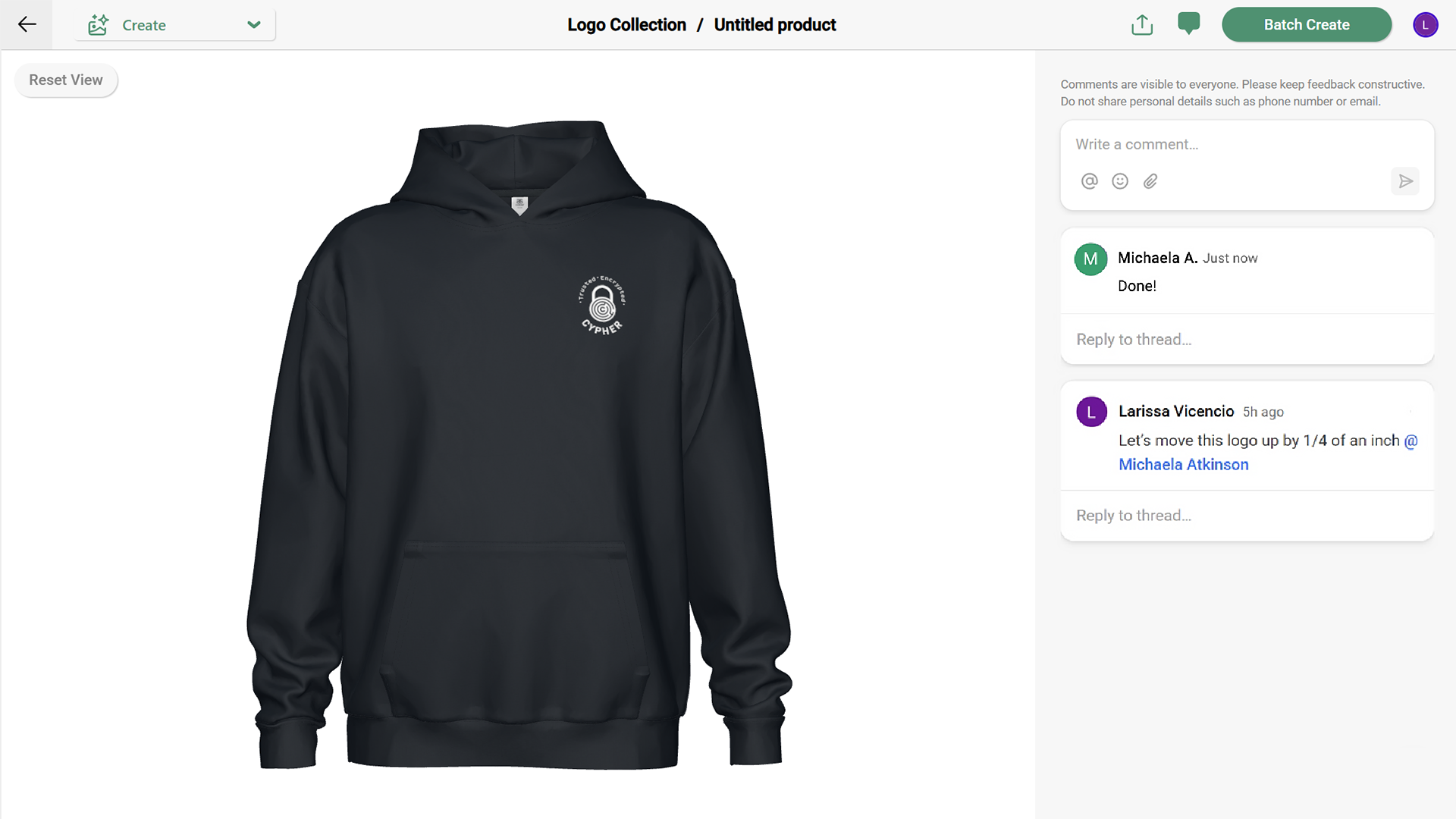

Step 2: Approval Process with Commenting & Sharing

Once a visual is created, it’s time to get stakeholder buy-in. The approval process is a critical stage in the overall project workflow. Decorator enables frictionless client approvals through simple sharing and in-platform commenting. Sales reps can send a link directly to the client or brand team, who can rotate, zoom, and inspect the 3D mockup from every angle.

Clients can comment directly on the design—pointing out tweaks in placement, sizing, or color—ensuring accuracy in the final approved mockup, streamlining feedback and avoiding long email threads or missed notes. This cuts revision rounds significantly and gets the order to production faster.

If sales reps prefer, they can also quickly and easily export images of products to drop them into their own standard presentations or line sheets. Visual selling is also a possibility, as sales reps can hop on a call and screen share the branded apparel in 3D, getting their customer’s feedback, making edits, and getting to approval in real-time. No matter the method, the speed at which sales reps are able to deliver visuals and confirm orders increases significantly with Decorator.

Step 3: Automated Tech Packs for Production

Once the design is approved, Decorator shifts from design tool to production pipeline. With the click of a button, it automatically generates a full tech pack based on the final mockup, including:

- Garment type and brand

- Decoration zones and techniques

- Artwork size and positioning across sizes

- Color and fabric specifications

- Plus the ability to add custom instructions and notes

This supports the development phase, transforming design concepts into production-ready instructions.

These files are tailored for decorators and screen printers, reducing costly errors and eliminating the manual work of converting visuals into production instructions. After exporting the tech pack, you can create and test samples to ensure fit and quality before full production. Performing a test run or sample order helps catch errors before mass manufacture. Automation reduces cost and helps you stay within budget compared to traditional, time-consuming manual processes.

Step 4: Incorporating Software into the Manufacturing Process

Decorator doesn’t replace your production systems, it complements them, and can be incorporated into existing systems for greater efficiency. Think of it as a visual layer that sits on top of existing processes, and acts as a single source of truth for everyone involved in bringing a branded apparel product to life. Tech packs can be exported and sent directly to fulfillment partners, decorators, or internal production teams. Since everything is built off standardized garment data and print zones, the final output aligns exactly with what was approved.

This makes it possible to achieve:

- Faster turnarounds

- Reduced misprints

- Easier tracking and version control

- Saving time and money through automation

- Supporting innovation and freeing up space for strategic growth

- Maintaining schedule and standardization

Decorator enables the creation of scalable, repeatable processes. The system supports different styles and printing requirements, and can be adapted for various workflows.

Step 5: Measuring Success and Feedback

Measuring success and gathering feedback are essential components of a thriving custom apparel business. By tracking key performance indicators such as production efficiency, quality control outcomes, and customer satisfaction, manufacturers gain valuable insights into their processes. This data-driven approach enables businesses to identify areas for improvement, make informed adjustments, and enhance overall efficiency.

Customer feedback plays a pivotal role in this process. Direct input from clients provides a clear picture of how well the final products and services align with expectations. By actively seeking and analyzing this feedback, businesses can refine their offerings, address any issues promptly, and foster stronger customer relationships. Sharing images and videos of finished apparel not only showcases quality but also helps build a compelling brand identity that attracts new customers.

By embracing best practices and continuously innovating, apparel businesses can stay ahead of the competition, achieve their goals, and deliver high-quality products that resonate with their customers. Ultimately, a focus on measuring success and acting on feedback is crucial for long-term growth and profitability in the custom apparel industry.

The Benefits of a Seamless End-to-End Flow

A modern apparel workflow isn’t just about design, it’s about aligning sales, creative, and production around the same source of truth. With SEDDI Decorator at the core, custom apparel businesses can:

- Close deals faster with interactive 3D previews

- Cut down approval cycles through direct collaboration

- Avoid costly errors and save time with automated tech packs

- Scale their operations without scaling manual tasks

From click to production, the businesses that own their workflow own the outcome.